From Prototype to series production

Since 1995 our company has focused on specialist automotive wiper systems. It began in the mid 1980’s through our own individual passions of motor sports and street used sports cars. This then developed into a serious business.

We are not only concerned with the conventional automotive industry, but also with manufacturers of municipal vehicle, combat vehicles, mini and midi buses, armoured cash-in-transit vehicles and large motor homes.

At our company in Duisburg, which is located in the heart of Germany where precision engineering has become a tradition over the last century, we can develop your wiper system from your initial product vision, through 3D design development to serial production. The range of products available is as varied as our range of customers themselves. We utilise a 3D CAD design system with synchronous technology and have the in-house experts available to create your first prototype. It does not matter if your wiper system is only very small, or simply a spare parts requirement, we are able to supply you with your requirements within short time parameters.

Your partner

- For your ongoing production

- For spare parts requirements of old wiper systems no longer manufactured by the industry (i.e. new editions)

- For customized products for prototypes, e.g. motor sports vehicles, solar vehicles

- For special requirements, e.g. military use in desert regions

- For lightweight construction for electric vehicles

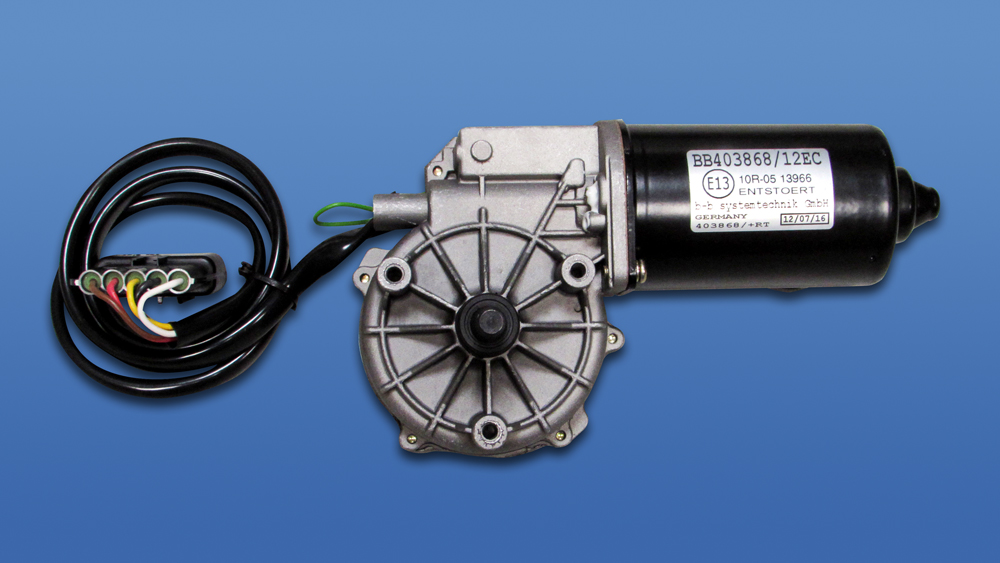

Wiper motors

Our portfolio covers a power range from just a couple of Newton meters up to a powerful 130Nm.

The speed levels are adapted to the requirements of the respective wiper system, these vary depending on the type of use and vehicle.

Generously dimensioned plain bearings guarantee a long service life and low-noise operation, with EMC testing in accordance with the R10 directive on request. Wiper motors are available for 24 volt and 12-volt vehicle electrical systems, with the 12 volt types a new wiper motor especially for the Fiat Ducato is now available (bb-EC-wiper-motor).

b-b EC-wiper-motor

After more than two years of R&D work, we are now able to offer you a windshield wiper motor that can be connected directly to the Fiat Ducato without the need for any additional switching equipment.

This new development eliminates the know problems with sliding contacts, in combination with sensitive body computers. The engine works completely contactless. Appropriate electronics monitor all functions and communicate with the vehicle's body computer. The software of the wiper motor has been precisely adjusted to the specifications of the Fiat body computer, thereby eliminating the possibility of misinterpretations or inexplicable error messages.

On request, the b-b-EC-wiper-motor is also available in a specific version. This enables the windshield wiper arms to be parked in the winter position, this means the wiper arms find their parking in the upright position.

Of course, the wiring set of the motor fits the original Fiat connector. All plug connections are sealed and correspond to the current state of the automotive industry.

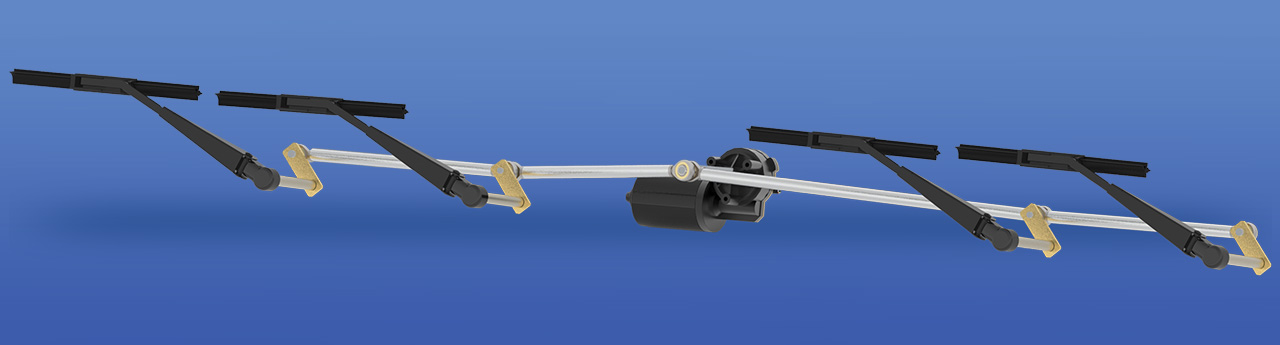

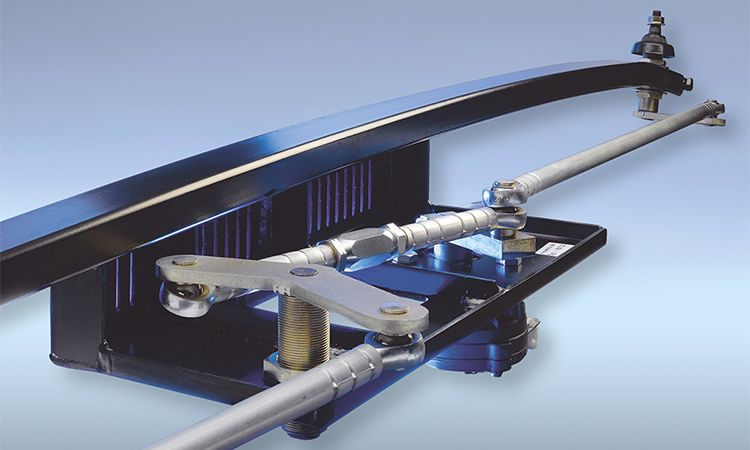

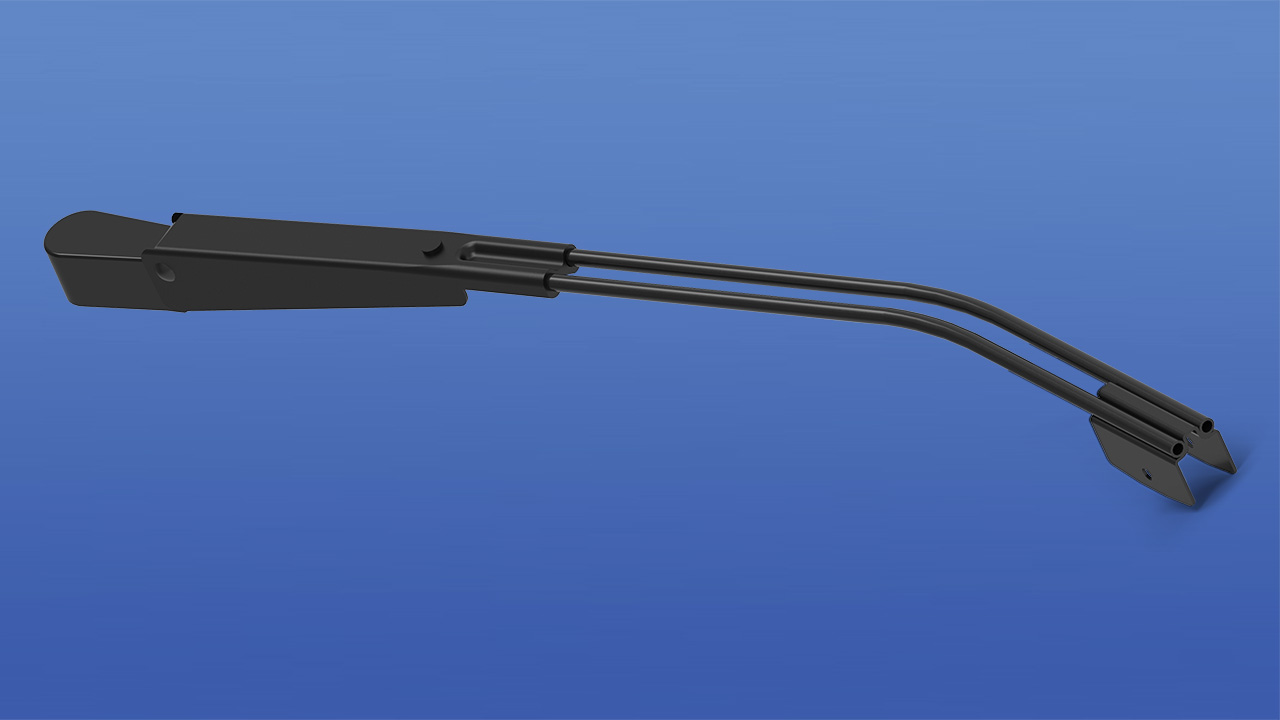

Components: wiper arms, wiper blades, linkage, wiper axles, support frames

Wiper arms are designed to the customer requirements, very small wiper arms with length of only 20cm up to over 1 meter are in our portfolio. All designed with particular attention to corrosion resistance or made in stainless steel.

Wiper blades from 200 mm up to 1,5 meters are also available, all of them subjected to elaborate galvanizing processes before undergoing powder coating. Wiper linkages are also weight-optimized through the consequent use of aluminum. Not only the push rods, but also the durable rod ends are made of aluminum or polymer plastics. Again, every pressing process is monitored by computer systems throughout the assembly process. Wiper axles are given a specific plasma coating that can withstand more than 300 hours in the salt spray chamber without any issues.

Every wiper system is Made in Germany and has been assembled in our production plant in Duisburg. Ongoing monitoring of the manufacturing tolerances as well as the monitoring of each individual pressing process during the final assembly of the wiper systems guarantees the highest level of production.

Furthermore, as lightweight materials play an increasing greater role in all future developments, reducing CO2 emissions is the keyword and is a vital aspect for all vehicles, while retaining durability and wear resistance in all kinds of environments. Therefore, we use aluminium, magnesium, high-performance plastic as polymer bearings and spherical bearings, tribologically optimized and 100 % lubrication free. Besides this, we are able to provide you with our special 3D Laser measurement unit (confirming to the EEC standard 78/318/EWG), enabling us to find out in advance of a expensive approval if there is any problem with your visual wiper field, to get the EEC 78/318/EWG permission.

b-b systemtechnik gmbh

Geschäftsführung: Dirk Bonrath, Jens Bonrath

Am Handwerkshof 2–6,

47269 Duisburg, Germany

Phone: +49 203 7135190

Fax: +49 203 7135191